Блог

In industrial production, pressure gauges are indispensable measurement instruments, widely used in mining, petroleum, chemical, power, and metallurgical industries. Selecting the right industrial pressure gauge not only ensures production safety and efficiency but also extends equipment service life. This article provides a detailed selection guide and answers to common questions about industrial pressure gauges. It also briefly introduces several related products from Zhaofeng Instruments to help you make the best choices during selection and use.

I.Basic Principles of Pressure Gauges

Mechanical Pressure Gauges | Electronic Pressure Gauges

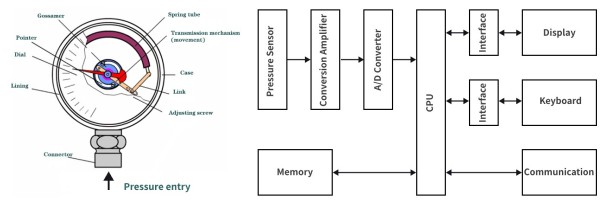

Industrial pressure gauges work by sensing and displaying the pressure of fluids (liquids or gases). Based on their working principles, they are mainly divided into mechanical pressure gauges and electronic pressure gauges. Mechanical types typically use Bourdon tubes or diaphragms as sensing elements, while electronic types rely on sensors and electronic circuits for pressure measurement.

II. Pressure Gauge Selection Guide

When selecting an industrial pressure gauge, the following factors should be considered:

1.Measuring Range

Choose a measuring range suitable for the actual application. Generally, the normal working pressure should not exceed two-thirds of the upper limit of the gauge’s range. For example, if the operating pressure is 6.3 MPa, a pressure gauge with a range of 0–10 MPa should be selected.

2.Accuracy Class

The accuracy class determines measurement precision. General-purpose gauges, capsule pressure gauges, and diaphragm gauges typically require Class 1.6 or Class 2.5. For precision measurement and calibration, mechanical pressure gauges with Class 0.4, 0.25, or 0.16 are recommended.

3.Connection Type

Ensure compatibility with the equipment’s connection type, such as threaded, flanged, or quick-coupling connections. Verify type and dimensions before selection.

4.Operating Environment

Environmental conditions greatly affect performance and service life. For high-temperature, low-temperature, or corrosive media, choose gauges designed for those conditions. Additional requirements such as anti-vibration, explosion-proof, or protective enclosures may also be necessary.

5.Special Functions

Depending on application needs, select pressure gauges with additional features such as electrical signal outputs, alarms, or remote transmission. These enhance measurement intelligence and enable easier monitoring and data management.

III. Zhaofeng Instrument Pressure Gauge Products

Product Series:

1. Y Series Standard Pressure Gauges

Suitable for measuring pressure of liquids, gases, or steam that are non-corrosive to the sensing element, under conditions with minimal pulsation or vibration.

Y-104 Radial Front-Edge Pressure Gauge Y-100 Vacuum Pressure Gauge

2. YZ Series Vibration-Resistant Pressure Gauges

Designed to withstand strong vibrations, pulsations, shocks, and sudden unloading. Filled with damping liquids such as silicone oil or glycerin for stable indication.

Y-150 Vibration-Resistant Pressure Gauge Y-150 Vibration-Resistant Pressure Gauge

(with color zone)

3. YB Series All-Stainless Steel Pressure Gauges

Widely used in processes requiring corrosion resistance, vibration resistance, or enhanced appearance. Vibration-resistant versions are filled with silicone oil or glycerin.

Y-101 Axial Front-Edge Stainless Steel Gauge Y-100J Radial EdgelessElectric Contact Pressure Gauge

4. YP Series Diaphragm Pressure Gauges

Use a diaphragm sensing element, suitable for viscous, crystallizing, or high-temperature fluids and gases. Typically used for low pressures up to 2.5 MPa.

YP-100 Diaphragm Pressure Gauge

5. YTP Series Diaphragm-Sealed Corrosion-Resistant Pressure Gauges

Use an indirect measurement structure, suitable for viscous, crystallizing, highly corrosive, or high-temperature fluids and gases. Made of stainless steel, with diaphragm options in various materials.

YTP-100 Diaphragm-Sealed Pressure Gauge

6. Special-Purpose Pressure Gauges

Custom-designed based on user needs, suitable for measuring oxygen, hydrogen, ammonia, and other special gases or environments, ensuring safe and reliable operation.

Main Technical Specifications:

1.Accuracy: Class 1.0 (special), Class 1.6, Class 2.5

2.Operating Temperature:

Standard: medium -20 to 70 °C; ambient -25 to 55 °C;

Special: medium -41 to 70 °C; ambient -41 to 60 °C

3.Vibration Resistance:

Standard: V.H.3;

Vibration-resistant: V.H.4 (per GB/T17214.3)

4.Sensing System Materials:

Bourdon tube: Tin bronze QSn4-0.3 or stainless steel 316L;

Connection: Copper alloy or stainless steel 304

Flange: Stainless steel 304 or specified materials

Diaphragm: Stainless steel 316L or specified materials

5.Case Materials:

Standard: Chrome-plated carbon steel;

Stainless Steel: 1Cr18Ni9Ti or 0Cr18Ni9

6.Typical Measuring Ranges:

Vacuum/compound ranges: -0.1–0; -0.1–0.15, 0.3, 0.5, 0.9, 1.5, 2.4

Pressure ranges: 0–0.1, 0.16, 0.25, 0.4, 0.6, 1, 1.6, 2.5, 4, 6, 10, 16, 25, 40, 60 MPa

IV. FAQs About Pressure Gauges

V. Installation, Maintenance, and Care

To ensure long-term stability, pressure gauges should undergo regular maintenance:

User Guide

1.Instrument Selection: For steady pressure, use 1/3–2/3 of the full scale; for fluctuating pressure, do not exceed 3/4 of the range.

2.Installation Environment: Avoid excessive vibration or pulsation. Use cooling elements when medium exceeds 70 °C. Select damping devices or liquid-filled types when pulsation or vibration is high.

3.Mounting: Install via instrument panel or support piping. Verify model/specifications before installation.

Maintenance

· Regular calibration: typically every six months

· Avoid mechanical shock or strong vibration

· Keep gauge clean

· Use corrosion-resistant types in harsh environments

· Stop use immediately and repair if leakage, damage, or pointer failure occurs; only reuse after qualified inspection

By following this selection guide and troubleshooting tips, you will better understand and operate industrial pressure gauges. For additional inquiries, feel free to contact us—we are committed to providing you with professional solutions.

Thank you for reading, and we wish you success in your work!

Note: The pressure gauges shown in this article represent only part of our product range. For more details, please visit our website, follow our social media channels, or reach out directly for consultation.