Блог

In the field of liquid level measurement and control, level transmitters and controllers play crucial roles. They work in conjunction to achieve precise regulation of liquid levels and are widely used in various industrial sites. The following is a list of some common level instruments:

1. Level Transmitters

a. Float-Type Level Transmitters

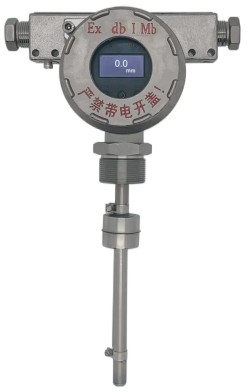

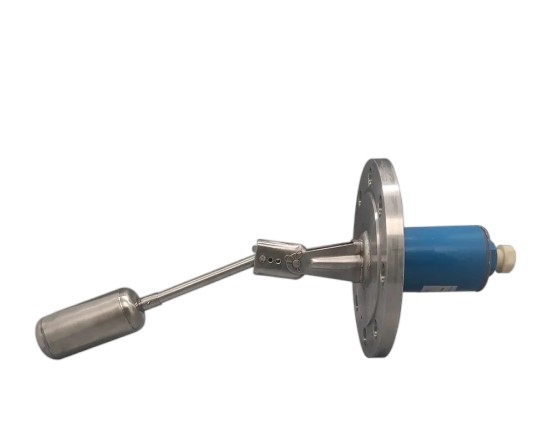

Float-type level transmitters adopt magnetic position sensors. The magnetic float moves up and down along the stainless steel protective tube with the liquid level, triggering the position sensor at the corresponding location. A conversion circuit then converts this signal into a current value corresponding to the float's position. Level transmitters are available in standard and explosion-proof types, and are suitable for industries such as metallurgy, chemical engineering, power generation, papermaking, and industrial sewage treatment.

GUC3000 Mining Explosion-Proof Level Sensor

ZF-UQB-(B) Series (Explosion-Proof) Float Ball Level Transmitter

b. Hydrostatic Level Transmitters

Hydrostatic level transmitters use dry ceramic capacitive or diffused silicon hydrostatic level sensors as sensing elements, combined with high-precision measurement, conversion, display, and control circuits. They feature a 4-20mA transmission output and can stably and accurately perform liquid level measurement in various industrial scenarios.

GUD10K Mining Explosion-Proof and Intrinsically Safe Liquid Level Transmitter

ZF-L Series Hydrostatic Level Transmitter

c. Magnetostrictive Level Transmitters

Magnetostrictive level transmitters are industrial automation instruments that achieve precise measurement of liquid levels (or interfaces) based on the magnetostrictive effect. Their core function is to convert the liquid level height into standard electrical signals such as 4-20mA and RS485, which are used for remote monitoring, data acquisition, or linkage with systems like PLC (Programmable Logic Controller) and DCS (Distributed Control System). They are widely applied in fields such as petroleum, chemical engineering, water treatment, food, and pharmaceuticals—where high requirements for measurement accuracy and stability are demanded.

ZF-CZ Series Explosion-Proof Magnetic Level (Displacement) Transmitter(Controller)

2. Level Controllers

a. Float-Type Level Controllers

Float-type level controllers use reed switches as control elements. The internal contacts have a large area, and inert gas protection enables them to switch high-voltage and high-current loads without sparks, resulting in minimal contact ablation and a long service life. They are suitable for liquid level control in domestic water tanks, water towers, oil tanks, and various acid-base storage tanks.

UQK-100(B) Series Float-Type (Explosion-Proof) Level Controller

KBU3000 Mining Explosion-Proof Float Level Switch

UQK-01/02/03 Liquid Level Switch

3. Level Gauges

a. Magnetic Float Level Gauge with Flip Columns

Magnetic float level gauges with flip columns adopt a "magnetic coupling + float" design. The magnetic float inside the container moves up and down with the liquid level. The permanent magnet inside the float drives the dual-color flip columns (usually red for "liquid present" and white/black for "liquid absent") outside the container to flip through magnetic field action, enabling continuous visual display of the liquid level. Some models can be equipped with a scale plate for accurate liquid level reading.

UHZ Flip-Column Magnetic Float Level Indicator

(Transmitter is configurable)

b. Ultrasonic Level Gauges

Ultrasonic level gauges realize liquid level measurement using the reflection principle of ultrasonic waves. Essentially, they calculate the distance from the probe to the liquid surface by measuring the time difference of the ultrasonic signal (transmit-reflect-receive), and then convert this distance into the liquid level height.

c. Radar Level Gauges

Radar level gauges measure liquid levels using the reflection characteristics of electromagnetic waves (radar waves) and belong to "microwave measurement technology". Their core principle is to transmit high-frequency radar waves (typically 6GHz, 26GHz, 80GHz), receive the radar waves reflected by the liquid surface, and then calculate the liquid level. Unaffected by air medium, temperature, or pressure, they are an industrial liquid level measurement solution with "strong adaptability".

Due to differences in application sites and functional requirements, the selection of models for liquid level measurement and control equipment varies. If you have any questions about model selection, please feel free to contact us—we will provide you with professional answers and support.

Which level product do you use most frequently? Welcome to leave a comment and share your experience!